-MinYeong Woo, Engineer, e-Motor Engineering Design Team 1

Q. What does the e-Motor Engineering Design Team 1 do and what are your current responsibilities?

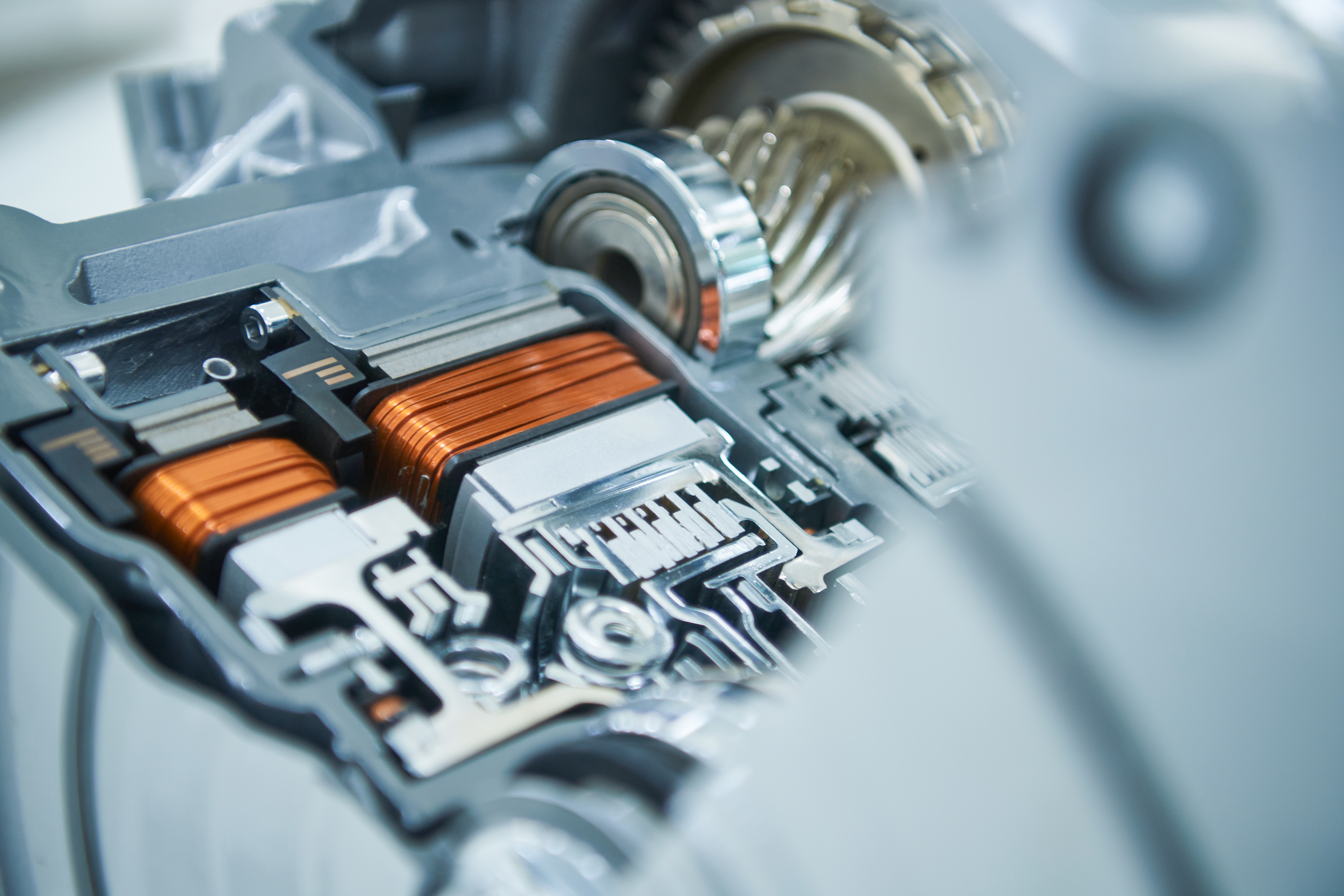

A. The e-Motor Engineering Design Team 1, part of the Electrification System Design Division, is responsible for the design of P1 and P2 traction motors used in Hyundai Motor Group’s next-generation hybrid systems. The team oversees the entire design process, including reviews of key components such as cores, magnets, and winding specifications to ensure optimal motor performance and efficiency. In addition, the team manages mass-production specifications, coordinates closely with suppliers, and provides technical support for global OEM partners.

In my role, I lead the electromagnetic design of the P1 motor applied in hybrid drive systems. My primary responsibility is reviewing and optimizing motor specifications to support its engine-starting and power-generation functions. I also manage the verification and quality evaluation of individual magnet specifications used in both P1 and P2 motors.

Q. What led you to choose a career in electromagnetic design?

A. While majoring in electrical and electronic engineering, I explored several potential career paths ranging from semiconductor research to power transmission and distribution. However, I felt more drawn to fields where I could directly observe mechanical operation, such as automotive engineering and robotics. My first exposure to motor design came through an electric machinery course, where I realized the discipline aligned closely with my long-standing interest in physics. As an undergraduate research student, I was able to deepen my technical understanding of the field, which further strengthened my confidence in this career direction. Since I genuinely enjoyed the work, I achieved strong academic results, and that positive feedback became a major source of motivation.

I was also inspired by the fact that motors play a central role not only in automobiles but also in trains, ships, and many other industries. The more I learned about their structures and operating principles, the stronger my desire became to pursue a long-term career in this field. This naturally led me to graduate studies and, ultimately, to my current position in electromagnetic design.

Q. Were there any differences between what you expected and what you actually experienced on the job?

A. In graduate school, most of my work was simulation-based, so the approach was largely theoretical. Research typically focused on optimizing conditions for specific applications and identifying ideal design solutions. In contrast, one of the biggest differences I encountered in the field was that every decision must be made within the practical constraints of mass production. Factors that were less prominent in simulations—such as supplier specification management, manufacturing tolerances, testing and reliability requirements, and cost considerations—have a direct and significant impact on actual designs. I also came to realize that even a single design change can trigger a chain reaction across multiple components and development processes. This systemic perspective became clear only through hands-on experience in the workplace.

Fortunately, during graduate school I was selected as a Hyundai Transys research scholarship student, which provided early exposure to real company projects. This experience allowed me to become familiar with industrial workflows in advance and significantly eased my transition after joining the company. I believe that students can greatly narrow the gap between academic theory and real-world practice by actively participating in industry–university collaboration programs offered at their institutions.

Q. What was the most difficult challenge after joining the company, and when did you feel the greatest sense of accomplishment?

A. During my early days at the company, learning internal systems and processes proved more challenging than the design work itself. Everything—from approval procedures to documentation formats—was new, and it took time to adapt. By learning step by step from senior researchers, I gradually became familiar with the workflow, though I still remember those initial months as both unfamiliar and demanding.

One of the most meaningful moments of accomplishment came when I served as project manager for the development of a technology roadmap (TRM) for an electrified system thermal analysis model. Thermal engineering was unfamiliar territory for me, as my background is in electromagnetics, and determining the initial development direction was particularly difficult. I revisited fundamental theories and sought guidance from senior colleagues whenever challenges arose, steadily moving the project forward. Despite numerous obstacles, I ultimately succeeded in developing a high-efficiency analysis model applicable to both electric vehicles and hybrid systems. Reaching the performance level we had set as our goal was extremely gratifying and remains one of the most rewarding achievements in my career to date.

Q. What advice would you give to someone preparing for a career in electrified motor design?

A. For those aiming to work with mechanical part drawings for mass-produced components, acquiring certifications in 2D and 3D CAD tools—such as Creo—and studying topics related to tolerance analysis can be very beneficial. For those interested in simulation-based roles involving motor specification development, including electromagnetic design, thermal analysis, and NVH analysis, gaining hands-on experience with analysis software such as JMAG, ANSYS Fluent, and ANSYS Motion will be highly valuable. Student versions of these tools are readily available, making them accessible for practice. Even basic exposure to simulation work can greatly enhance understanding of real-world development processes. That said, using software tools and truly designing are two different skills. It is essential to develop the ability to interpret simulation results correctly and understand them structurally rather than relying solely on tool operation.

Ultimately, I believe that hands-on design experience is the most powerful asset. I strongly recommend taking courses related to motors, inverters, and control systems—whether within or outside your formal academic program—and seeking opportunities through internships, undergraduate research programs, or graduate studies to participate directly in relevant projects. Even small self-initiated projects are extremely valuable. Documenting simulation results throughout the process and seeking feedback from professors or industry professionals can significantly accelerate learning and professional growth. While theoretical study forms an important foundation, many critical skills are gained only through practical application. Moving beyond conceptual understanding to firsthand experience and continuous practice will become your true competitive advantage.

Q. What is the working atmosphere like in the e-Motor Engineering Design Team 1?

A. Within our team, collaboration comes naturally, with no rigid divisions between roles or responsibilities. While each member manages assigned components, motor development involves numerous parts and multiple suppliers, which often presents challenges that cannot be addressed individually. Since the system is highly interconnected, we have established a workflow in which design and quality issues are openly discussed as a team, and decisions on direction are made collectively.

In situations requiring team-level perspective—such as manufacturing process concerns or changes in supplier production sites—we share data from our respective areas and consolidate our perspectives to determine the best course of action. For example, when a plant requests a design review or additional testing is required for a new component, we collaborate by dividing necessary tasks and supporting one another. This culture of mutual assistance not only enhances operational efficiency but also creates a reassuring and supportive working environment.

Q. What does your after-work routine look like?

A. After work, I usually unwind by exercising or playing games. Since my job requires sustained mental focus, physical activity helps release tension from the day. Playing games or watching light entertainment content on YouTube also allows me to relax and clear my mind. By taking time to switch off mentally, I feel refreshed and reenergized, ready to concentrate fully the following day. These moments of relaxation are especially meaningful to me, as they provide valuable balance and comfort in my daily routine.

Q. Lastly, what do your work and your workplace mean to you?

A. I believe that my work and workplace play a significant role in shaping who I am as an engineer. In my early days at the company, organizational changes sometimes made it difficult to clearly define my role within motor design. However, as I began participating in projects where my designs were carried through to actual production vehicles, I developed a strong sense of pride in my work as a motor design engineer. Along with that pride, my sense of responsibility deepened, and I gained a clearer understanding of the value of what I contribute.

At the same time, I have begun to define a clear direction for my future growth. Beyond electromagnetic design, I hope to become an engineer with a comprehensive understanding of the motor as an integrated system, including related disciplines such as thermal engineering and testing. By broadening my technical perspective, I hope to contribute more meaningfully to our team’s decision-making processes and ultimately grow into an engineer who helps position Hyundai Transys as a technological leader in its field.

'Global' 카테고리의 다른 글

| Seat Design That Shapes the Mobility Experience (0) | 2025.12.29 |

|---|---|

| The Ultimate Stage of Powertrain System Development (0) | 2025.12.04 |

| Designing the Spaces and Experiences of Future Mobility Through Technology (0) | 2025.11.04 |

| Ensuring Customer Satisfaction Through Quality Assurance (0) | 2025.10.31 |

| The Art of Turning Design Blueprints into Products (0) | 2025.10.31 |